The Ultimate Guide to Efficiency in Material Handling: Optimizing Design, Processes, and Global Collaboration

Introduction

Efficiency in material handling is the foundation of a well-functioning intralogistics operation. From strategic resource allocation in layout design to ensuring the accuracy of a Bill of Materials (BOM), leveraging global teamwork, and preventing costly errors, every step matters. This guide brings together the key principles of material handling efficiency, offering a roadmap to success for companies looking to optimize their operations.

1. Strategic Resource Allocation in Layout Design

A well-designed material handling layout maximizes space, minimizes handling time, and enhances adaptability. However, achieving an optimal layout requires strategic resource allocation.

Key Challenges in Layout Design:

-

Integrating diverse components like conveyors, AS/RS, and robotics.

-

Ensuring data accuracy for forecasting and inventory levels.

-

Overcoming software complexity with the right training.

Best Practices:

-

Invest in Advanced Software: Tools with simulation capabilities and optimization algorithms streamline design, much like CET Material Handling facilitates intuitive and efficient layout planning.

-

Prioritize Training: Skilled engineers can reduce errors and optimize layouts.

-

Balance Costs and Benefits: Conduct thorough cost-benefit analyses to justify investments.

Read more about effective resource allocation in layout design.

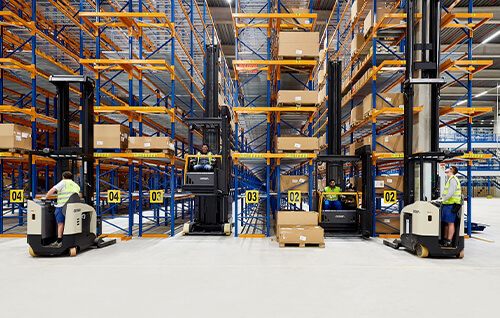

An efficient layout optimizes space, reduces handling time and allows for future changes.

2. The Importance of an Accurate BOM

A Bill of Materials (BOM) serves as the backbone of material handling projects. Errors in the BOM can lead to costly delays and inefficiencies.

Benefits of an Accurate BOM:

-

Minimizes project delays by ensuring timely material procurement.

-

Reduces costs through optimized inventory management.

-

Improves collaboration across design, procurement, and installation teams.

Optimizing BOM Management:

-

Integrate BOM with ERP Systems: Centralized platforms enhance forecasting and inventory control.

-

Leverage Automation: Modern software solutions, such as CET Material Handling, streamline BOM creation, reducing manual errors.

Discover how an accurate BOM drives success.

An accurate BOM has to account for materials from A like AGV to Z like Zip Tie

An accurate BOM has to account for materials from A like AGV to Z like Zip Tie

3. Leveraging Global Teamwork in Material Handling

With international supply chains and distributed teams, collaboration is key to optimizing intralogistics.

How Global Teamwork Enhances Efficiency:

-

Boosts Productivity: Diverse expertise leads to innovative solutions.

-

Smooths Workflows: Shared data and communication tools minimize delays.

-

Enables 24/7 Progress: Different time zones keep projects moving continuously.

Essential Tools for Global Collaboration:

-

Cloud-based platforms for real-time access to information.

-

Project management software to track tasks and timelines.

-

Advanced communication tools to bridge geographical gaps.

-

Collaborative design tools like CET Material Handling, ensuring that teams can seamlessly work on and refine layouts together.

Learn more about the power of global teamwork.

.jpg?width=600&height=399&name=nasa-Q1p7bh3SHj8-unsplash%20(1).jpg) When teams are spread across different continents and time zones, staying connected is critical

When teams are spread across different continents and time zones, staying connected is critical

4. Optimizing Layouts with CET Material Handling

CET Material Handling revolutionizes layout design by offering an intuitive 2D/3D environment to visualize and optimize facility layouts.

Benefits of Using CET Material Handling:

-

Identifies bottlenecks early through interactive simulations.

-

Enables space optimization by testing different configurations.

-

Improves workflow efficiency by streamlining material movement.

Real-World Application:

A distribution center used CET Material Handling to optimize high-traffic zones, reducing congestion and improving order processing efficiency.

Explore how CET Material Handling transforms layout design.

.png?width=600&height=327&name=CET%20MH%2015.5%20Screenshot%203%201%20(1).png)

Visualizing efficiency in action: CET Material Handling makes complex layout design intuitive

5. The Cost of Early vs. Late-Stage Errors

Mistakes in material handling design can have significant financial and operational consequences.

Early-Stage Errors:

-

Easier to correct but still impact project timelines.

-

Can be prevented with robust software, accurate data, and team collaboration.

Late-Stage Errors:

-

Require costly modifications to infrastructure and systems.

-

Lead to severe project delays and increased operational costs.

Prevention Strategies:

-

Use Advanced Software: CET Material Handling provides real-time error detection and proactive design validation.

-

Ensure Data Accuracy: Strict quality control prevents costly mistakes.

-

Encourage Cross-Functional Reviews: Collaboration among teams catches inconsistencies early.

Avoid costly errors with these best practices.

Avoiding Errors with Automatic Clash Detection and Optimal Path Creation in CET Material Handling

Conclusion

Efficiency in material handling requires a strategic approach across multiple fronts—from smart layout design and accurate BOM management to global collaboration and proactive error prevention. By leveraging advanced tools like CET Material Handling and adopting data-driven decision-making, companies can optimize their operations, reduce costs, and enhance competitiveness.

Want to stay ahead in the material handling industry? Start optimizing today!

Subscribe to our blog to stay at the forefront of innovation and best practices in the material handling industry.