.jpg?width=300&name=sven-mieke-fteR0e2BzKo-unsplash%20(1).jpg)

Optimizing Layouts and Creating Success Stories with CET Material Handling.

The Importance of Layout Optimization

In material handling and intralogistics, the efficiency of a layout can significantly impact daily operations. From reducing travel distances to optimizing storage space, thoughtful design helps businesses operate more smoothly and efficiently. But achieving that ideal layout is often easier said than done

The Challenge of Inefficient Layouts

Many facilities deal with inefficiencies due to suboptimal layouts. These inefficiencies might show up as unnecessary equipment movement, frequent congestion points, or inconsistent material flow. The result? Higher operational costs and slower throughput.

Traditionally, layout planning involved guesswork, manual adjustments, and time-consuming revisions. While these methods worked in the past, today’s dynamic industry calls for a more adaptable, data-informed approach.

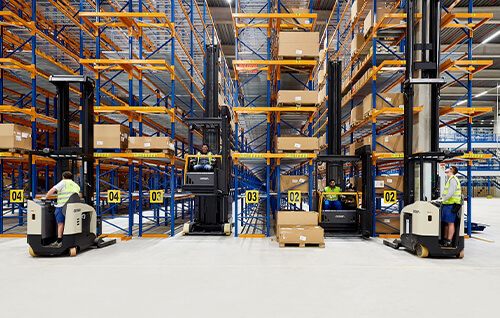

Clean and efficient layouts enhance productivity and reduce bottlenecks.

A Smarter Way to Approach Layout Optimization

Modern layout planning tools offer new ways to visualize and test different configurations without disrupting operations. One such tool is CET Material Handling, which supports layout optimization through interactive design and practical visualization. By seeing the layout in both 2D and 3D, users can better understand how equipment, workflows, and materials interact.

These insights help facilities:

- Identify potential bottlenecks early

- Explore different layout options before making physical changes

- Use space more effectively

Key Focus Areas for Efficient LayoutsWhen optimizing a material handling layout, there are a few critical factors to consider:

|

Practical Applications in the Industry

In a recent layout redesign, a distribution center used software-based planning to rearrange its high-traffic zones. The updated layout reduced travel distances and minimized congestion, helping the facility process orders more efficiently during peak seasons. Another warehouse found that reconfiguring storage locations based on material movement patterns helped reduce equipment wear and tear.

.png?width=600&height=327&name=CET%20MH%2015.5%20Screenshot%203%201%20(1).png)

Visualizing efficiency in action: CET Material Handling makes complex layout design intuitive

Tools like CET Material Handling can assist in these types of projects by providing clear visualizations and flexible design options, making it easier to test ideas before committing to changes.

Looking Ahead: The Role of Technology in Layout Design

As the industry continues to evolve, more facilities are turning to technology-driven design processes. These tools not only improve the efficiency of today’s operations but also create layouts that can be adapted as needs change.

Subscribe to the Configura Blogs to get notified whenever we post something new: