Effective Resource Allocation in Material Handling Layout Design

Optimizing Your Intralogistics: How Strategic Resource Allocation Impacts Layout Design

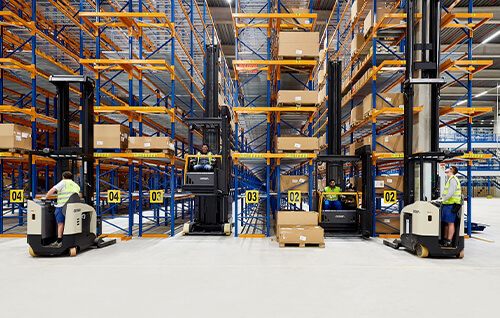

A well-designed material handling layout is crucial for efficient and cost-effective intralogistics operations. However, creating such a layout requires strategic resource allocation, from investing in the right technology to training your team effectively.

The Importance of Initial Layout Design

The initial layout design sets the stage for your entire material handling operation. A well-planned layout optimizes space utilization, minimizes material handling time, and reduces the risk of damage to goods. It also provides the flexibility to adapt to future changes and expansions.

An efficient layout optimizes space, reduces handling time and allows for future changes.

Common Challenges in Layout Design

Creating an effective material handling layout is not without its challenges. Some common pain points include:- Integrating diverse components: Successfully incorporating conveyors, AS/RS, robotics, and other automated systems requires careful planning and coordination.

- Data accuracy and forecasting: Reliable data on inventory levels, order patterns, and workflow processes are essential for designing a layout that meets current and future demands.

- Software complexity: Modern material handling design software can be complex, requiring specialized knowledge and skills.

Top 3 Considerations for Resource AllocationTo overcome these challenges and ensure a successful layout design, consider these key resource allocation aspects:

|

The Impact of Training

Investing in comprehensive training for your engineers is essential for maximizing the efficiency of your layout design process. Well-trained engineers can:

- Reduce design time: Proficient software users can create layouts more quickly, leading to faster project completion.

- Minimize errors: A deep understanding of the software and design principles helps prevent costly mistakes and rework.

- Optimize layouts: Skilled engineers can leverage advanced software features to create highly efficient and adaptable layouts.

Unlocking Long-Term Success

By strategically allocating resources to invest in advanced software, provide comprehensive training, and conduct thorough cost-benefit analyses, you can create a highly efficient material handling layout that drives long-term success.

Strategizing optimal resource allocation is crucial for long-term success.

Effective resource allocation in layout design is an investment in the future of your intralogistics operations. By prioritizing the right resources, you can optimize your material handling processes, reduce costs, and enhance your competitive advantage.

Subscribe to our blog to receive valuable insights on optimizing your material handling operations.