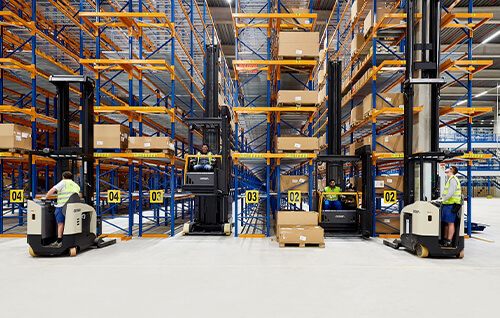

ASRS

This powerful tool allows you to seamlessly integrate AS/RS cranes into your warehouse layout, optimizing vertical space and streamlining material handling processes. Visualize the movement of goods and ensure seamless integration with other warehouse components, such as conveyors and racking systems.

Design and visualize automated storage and retrieval systems

This powerful tool allows you to seamlessly integrate AS/RS cranes into your warehouse layout, optimizing vertical space and streamlining material handling processes. Visualize the movement of goods and ensure seamless integration with other warehouse components, such as conveyors and racking systems.

Essential AS/RS is ideal for:

- High-volume warehouses

- Distribution centers with limited floor space

- Facilities seeking to improve order fulfillment speed and accuracy

Guarding

CET ESSENTIALS MATERIAL HANDLING

Prioritize safety and compliance with Essential Guarding. Easily incorporate guardrails, bollards, and other safety features into your warehouse design.

"Due to the software’s efficiency, a single design project that used to take up to two days to complete can now be done in half a day’s time."

– Yoran Van Eekert, E’log Automation

-

Any warehouse or distribution center

-

Facilities with high pedestrian or forklift traffic

-

Operations prioritizing a strong safety culture

- TYPES OF GUARDING

- WAREHOUSE SAFETY AND COMPLIANCE

TYPES OF GUARDING

- Machine Fencing (including doors and service openings): These physical barriers safeguard workers from hazardous machinery and equipment. Machine fencing can be customized with doors and service openings to allow controlled access for maintenance or operation.

- Light Curtains and Safety Scanners: These optoelectronic devices create an invisible barrier that triggers a stop command when breached, protecting personnel from hazardous areas. They are ideal for applications requiring frequent access while maintaining safety.

- Barriers: These physical barriers define safe walkways for pedestrians, separating them from forklift traffic, machinery, and other hazards. Barriers can be constructed from various materials, including metal, plastic, or concrete.

- Pole Barriers: These versatile barriers consist of interconnected poles and rails, offering flexibility in creating temporary or permanent safety zones. They are commonly used to cordon off areas under construction, maintenance, or potential hazards.

- Guard Rails: These sturdy rails provide a physical barrier to prevent falls from elevated platforms, mezzanines, or open edges. Guard rails are crucial for ensuring worker safety in areas with height differences.

WAREHOUSE SAFETY AND COMPLIANCE

By incorporating these guarding solutions, you can:

- Prevent accidents: Minimize risks of collisions and falls.

- Protect equipment: Safeguard valuable assets from damage.

- Enhance productivity: Foster a safe and efficient work environment.

- Ensure compliance: Meet regulatory requirements for warehouse safety.

CET Essentials for Material Handling allows you to analyze potential hazards, optimize safety measures, and ensure your warehouse complies with industry best practices.

MORE ESSENTIAL EXTENSIONS

Streamline material handling and reduce manual labor.