ASRS

This powerful tool allows you to seamlessly integrate AS/RS cranes into your warehouse layout, optimizing vertical space and streamlining material handling processes. Visualize the movement of goods and ensure seamless integration with other warehouse components, such as conveyors and racking systems.

Design and visualize automated storage and retrieval systems

This powerful tool allows you to seamlessly integrate AS/RS cranes into your warehouse layout, optimizing vertical space and streamlining material handling processes. Visualize the movement of goods and ensure seamless integration with other warehouse components, such as conveyors and racking systems.

Essential AS/RS is ideal for:

- High-volume warehouses

- Distribution centers with limited floor space

- Facilities seeking to improve order fulfillment speed and accuracy

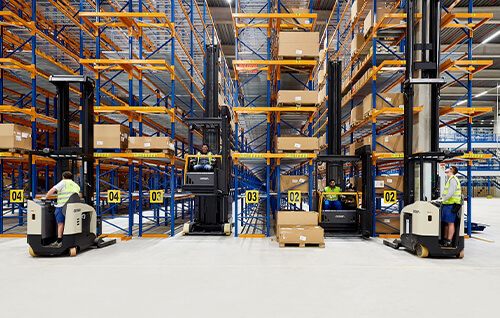

Deep Racking

CET ESSENTIALS MATERIAL HANDLING

Maximize your storage density with specialized deep racking systems. Design and visualize push-back, drive-in, and pallet flow systems to optimize your warehouse space.

"Due to the software’s efficiency, a single design project that used to take up to two days to complete can now be done in half a day’s time."

– Yoran Van Eekert, E’log Automation

-

Warehouses with high-volume storage needs

-

Cold storage facilities

-

Operations requiring specialized storage solutions

- TYPES OF DEEP RACKING

- OPTIMIZE YOUR WAREHOUSE

- KEY CONSIDERATIONS

TYPES OF DEEP RACKING

- Drive-In Rail: This system allows forklifts to enter the rack structure for loading and unloading pallets, maximizing space utilization. It's ideal for bulk storage of similar items with a LIFO (last-in, first-out) inventory rotation.

- Drive-Through Rail: Similar to drive-in racking, but with access from both sides, offering more flexibility and slightly improved selectivity.

- Push-Back Rail: This dynamic system uses nested carts that slide backward on inclined rails, allowing for a FIFO (first-in, first-out) inventory rotation. It combines high density with improved selectivity compared to drive-in racking.

- Pallet Live Rail: This gravity-fed system utilizes a slight incline to allow pallets to flow smoothly from the loading aisle to the unloading aisle. It ensures FIFO inventory rotation and is ideal for high-volume, time-sensitive goods.

- Shuttle Systems: Automated shuttles move pallets within the racking structure, increasing efficiency and reducing the need for forklift travel. This system offers high density and can be configured for both FIFO and LIFO.

- Hybrid Solutions: For ultimate flexibility, consider combining different deep racking types to create a customized solution that meets your specific needs. For example, you might use drive-in racking for bulk storage and pallet flow racking for high-turnover items.

OPTIMIZE YOUR WAREHOUSE

KEY CONSIDERATIONS

- Inventory turnover: How frequently do you need to access pallets?

- Product variety: Are you storing a wide variety of goods or mostly similar items?

- Space constraints: How much space do you have available?

- Material handling equipment: What type of forklifts do you use? By carefully evaluating these factors with the help of CET Essentials for Material Handling, you can select a deep racking system that optimizes your warehouse operations and maximizes storage capacity.

MORE ESSENTIAL EXTENSIONS

Streamline material handling and reduce manual labor.