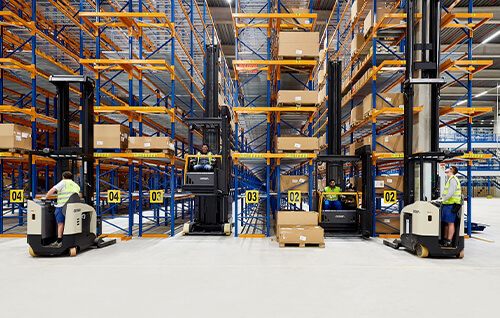

ASRS

This powerful tool allows you to seamlessly integrate AS/RS cranes into your warehouse layout, optimizing vertical space and streamlining material handling processes. Visualize the movement of goods and ensure seamless integration with other warehouse components, such as conveyors and racking systems.

Design and visualize automated storage and retrieval systems

This powerful tool allows you to seamlessly integrate AS/RS cranes into your warehouse layout, optimizing vertical space and streamlining material handling processes. Visualize the movement of goods and ensure seamless integration with other warehouse components, such as conveyors and racking systems.

Essential AS/RS is ideal for:

- High-volume warehouses

- Distribution centers with limited floor space

- Facilities seeking to improve order fulfillment speed and accuracy

CONVEYORS

CET ESSENTIALS MATERIAL HANDLING

Design efficient material handling systems with ease. Quickly add and configure various conveyor types, including curves, inclines, and declines, to optimize material flow.

"Due to the software’s efficiency, a single design project that used to take up to two days to complete can now be done in half a day’s time."

– Yoran Van Eekert, E’log Automation

-

Manufacturing facilities

-

Distribution centers

-

Warehouses with complex material handling needs

- DESIGN AND OPTIMIZE

- ENHANCE EFFICIENCY AND SAFETY

DESIGN AND OPTIMIZE

CET Essentials for Material Handling enables you to create a 3D warehouse layout and visualize your conveyor system in real-time. Make use of different conveyor types and accessories, including:

- Transportation Conveyors: These workhorses are designed to move materials from one point to another, typically over longer distances. They come in various forms, including belt conveyors, roller conveyors, and chain conveyors, each suited for different types of loads and environments.

- Accumulation Conveyors: These conveyors allow for the temporary accumulation or buffering of products, providing flexibility in your production line. They can help regulate product flow, prevent bottlenecks, and provide space for operations like labeling or inspection.

- Gravity Conveyors (including Spirals): Harnessing the power of gravity, these conveyors use inclined surfaces or spirals to move products downwards. They are energy-efficient and ideal for applications where elevation changes are required.

- Sortation Conveyors (Crossbelt, Shoe Sorter, Linear Crossbelt, Narrow Belt Sorter): These advanced systems automatically sort and divert products to different destinations based on predefined criteria. They are crucial for high-speed distribution centers and e-commerce fulfillment operations.

- Transfer Conveyors: These conveyors facilitate the transfer of products between different conveyor lines or sections. They can be used to merge, divert, or rotate products, ensuring smooth transitions within your material handling system.

- Lift Conveyors: These conveyors are designed to elevate or lower products between different levels. They are commonly used in multi-level facilities or to integrate with mezzanines and platforms.

- Guarding for Conveyors: Safety is paramount. Incorporate guarding solutions around your conveyors to protect personnel from moving parts and pinch points.

- Chute Conveyors: These simple yet effective conveyors use gravity to transport items down an inclined chute. They are ideal for moving products between different levels or for applications requiring a controlled descent.

- Pallet Conveyors (Chain, Roller, Table, Lift): Specifically designed for handling palletized loads, these conveyors provide efficient and reliable transportation of heavy goods throughout your facility. They come in various configurations to suit different needs and layouts.

ENHANCE EFFICIENCY AND SAFETY

MORE ESSENTIAL EXTENSIONS

Streamline material handling and reduce manual labor.