ASRS

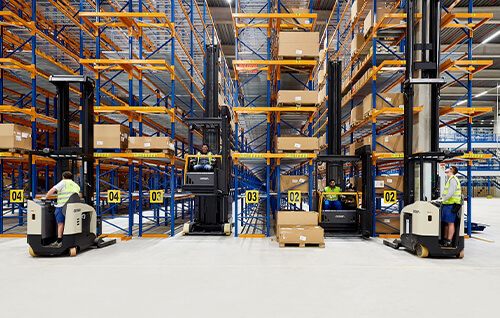

This powerful tool allows you to seamlessly integrate AS/RS cranes into your warehouse layout, optimizing vertical space and streamlining material handling processes. Visualize the movement of goods and ensure seamless integration with other warehouse components, such as conveyors and racking systems.

Design and visualize automated storage and retrieval systems

This powerful tool allows you to seamlessly integrate AS/RS cranes into your warehouse layout, optimizing vertical space and streamlining material handling processes. Visualize the movement of goods and ensure seamless integration with other warehouse components, such as conveyors and racking systems.

Essential AS/RS is ideal for:

- High-volume warehouses

- Distribution centers with limited floor space

- Facilities seeking to improve order fulfillment speed and accuracy

Cantilever Racking

CET ESSENTIALS MATERIAL HANDLING

Efficiently design and visualize cantilever racking systems for storing long and bulky items. Utilize placeholders to quickly explore different configurations and maximize your vertical storage space.

"Due to the software’s efficiency, a single design project that used to take up to two days to complete can now be done in half a day’s time."

– Yoran Van Eekert, E’log Automation

-

Storing long and bulky items such as lumber, pipes, and tubing

-

Maximizing vertical storage space in warehouses

-

Creating efficient and organized storage solutions

- OPTIMIZE YOUR WAREHOUSE

- KEY CONSIDERATIONS

- CANTILEVER RACKING APPLICATIONS

OPTIMIZE YOUR WAREHOUSE

Cantilever racking utilizes vertical space by storing items horizontally on adjustable arms, maximizing storage capacity and improving accessibility. Design your ideal system in CET Essentials for Material Handling, creating a 3D warehouse layout and visualizing your cantilever racking in real-time.

- Versatile Profiles: Choose from a wide range of column and arm profiles, including IPE and AISC S profiles, to meet your load capacity and dimensional requirements.

- Adjustable Arms: Easily adjust arm positions and lengths to accommodate different load sizes and maximize vertical space.

- Customizable Base Design: Configure base lengths and depths to ensure stability and proper load distribution.

- Safety Features: Incorporate roll-off protectors to prevent accidental falls and ensure a safe working environment.

- Real-time Visualization: See your cantilever racking design come to life in 3D, allowing you to evaluate clearances, access points, and overall layout effectiveness.

- Accurate Specifications: Generate detailed specifications and bills of materials directly from your CET design, streamlining procurement and installation.

KEY CONSIDERATIONS

- Cantilever arm length: Select the right arm length to accommodate various item sizes.

- Cantilever load capacity: Ensure the system can safely support heavy loads.

- Cantilever base design: Choose a stable base for optimal safety and load distribution.

CANTILEVER RACKING APPLICATIONS

- Lumber storage

- Pipe storage

- Building material storage

- Industrial storage with unique needs

MORE ESSENTIAL EXTENSIONS

Streamline material handling and reduce manual labor.