On the Move - Episode 3 - What is Parametric Manufacturing?

Part numbers were created to track and identify different parts and products within a manufacturer. Their purpose was to standardize the way items are tracked and create efficiencies within the manufacturing process.

As manufacturers continue to evolve and grow their product offering, the number of part numbers continues to grow until its almost uncontrollable. Manufacturers could have thousands, if not hundreds of thousands of different part numbers to keep track of. Not to mention, that information lives in various tools throughout the manufacturing process, so the complexity of part number maintenance becomes an even greater burden.

Part numbers are necessary to sell products, but what happens when a customer requests a product that doesn’t exist (some manufacturers call this a special)? Without a part number to assign, sales must work with production to create a special part number which can be time consuming and costly.

Now if the manufacturer has a low number of products and they manufacturer to stock, then part numbers can be an efficient and effective way to track items. But if a manufacturer has many products with many variations, it can quickly become unmanageable.

So how do you handle the growing complexity of part numbers? Eliminate part numbers and embrace parametric manufacturing to make selling various types of products simple.

What is parametric manufacturing?

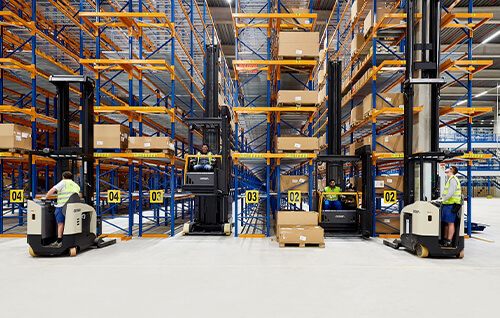

Parametric manufacturing moves away from using part numbers to dictating what products are possible to manufacturers. Instead, it focuses on algorithms and parameters to determine the thousands of product variations a manufacturer could create. Both the algorithms and parameters could be based on product features, relationships with other products, manufacturing machinery limitation and more.

By using algorithms and parameters, manufacturers can focus on providing unlimited variations of a product without it having to be a separate process to develop a special part number.

Parametric Manufacturing Example

Imagine a manufacturer is selling workstations. They keep it simple by going to market with two variations, one that is A length by A width and one that is B length and B width and each only come in one finish.

A new customer comes to them and wants to purchase a C length and C width workstation. The manufacturer can either decide to only sell what they produce or go down the rabbit hole of creating a special to gain the customer.

Instead of creating a process to handle special orders, the manufacturer should consider how to handle a larger variety of product variations before the product goes to market.

Let’s go back to the workstation, instead of only selling two product variations with specific product numbers, what if the manufacturer used algorithms, product types and parameters to determine what products could be offered.

The algorithms could generate information needed throughout the entire process, from sales through manufacturing, delivery and installation.

It could handle pricing, graphics, quotes, bill of materials, building information, modeling data, production sheets, CNC machine code, installation documents and more.

The manufacturer moves from static data to dynamic data generated by algorithms that adapt to customer requirements, handled automatically by technology.

With part numbers, manufacturers must understand what they should sell before they even sell anything. With algorithms, manufacturers don’t need to understand what the customer will purchase ahead of time. They will be prepared to sell whatever the customer asks for within certain constraints setup by sales and production. All of this can be handled by technology.

Now, I know what you’re thinking – this sounds like magic. How does one even begin to think about eliminating part numbers and developing a new process from scratch – but its possible. In fact, there are manufacturers already utilizing parametric manufacturing.

To begin the journey to parametric manufacturing, manufacturers must first need to separate the market from manufacturing. The trick is to make sure that manufacturing doesn’t know anything about the market. They must trust and rely on that the algorithm is correct.

On the market side, customers and designers use the algorithm to create variations of a product, stretching and applying finishes. Simultaneously the algorithm assists them with what you can and cannot do with the product.

In the background, the algorithm dynamically generates pricing and the 3D digital representation of the actual product, so nothing has to be pre-defined in any database.

When the customer is satisfied, the clean order is sent straight to manufacturing. That is parametric manufacturing.

Want to learn how you can say goodbye to part numbers and hello to parametric manufacturing? Schedule time to meet with a Configura representative to learn more or download our free resource on 'Parametric Manufacturing'. This outline is a good starting point to learn more about how your company can take full advantage of configurable products.

on the move series

EPISODE 2 - WHY DO WE HAVE INDUSTRIES?

EPISODE 1 - VALUATING CUSTOMER-CENTRIC SOFTWARE