Safety Should Always Be Perfectly Synced, Every Step of the Way

When used efficiently, space planning and design software can ensure warehouse safety and compliance requirements, as well as automate and streamline day-to-day manufacturing processes. Here’s how four companies are finding big success after implementing smart design software.

On average, every seven seconds a worker in the United States is injured. That’s nearly 4.7 million workers each year. From minor sprains and strains, to slips, falls or collisions, injury is bad for workers and costly for companies—and these figures just represent the USA.

Employers that implement effective safety and health programs may expect to significantly reduce injuries and illnesses and reduce the costs associated with these injuries and illnesses, including workers' compensation payments, medical expenses and lost productivity.

The US Occupational Health and Safety Administration states employers often find that process, and other changes made to improve workplace safety and health, may result in significant improvements to their organization's productivity and profitability.

SAFETY & THE MATERIAL HANDLING INDUSTRY

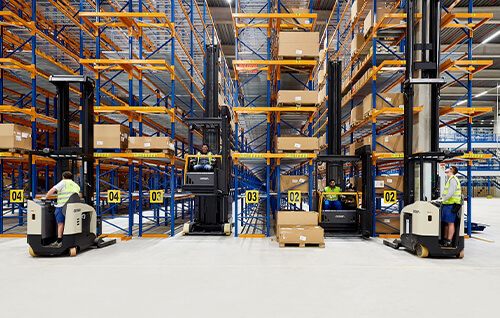

Think about it: manufacturers must not only manufacture products, but also configure warehouse spaces that support the manufacturing process. From pallet racking to conveyor systems, the material handling industry is complex. No warehouse is the same.

Material handling is defined as the movement, protection, storage and control of materials and products throughout manufacturing, warehousing, distribution, consumption and disposal.

The development of an efficient warehouse plan requires a large team of engineers and designers working together to solve for machine needs, human needs, overall floorplan space and manufacturing safety and compliance requirements.

Over the last five to 10 years, the material handling industry has experienced significant growth. There is high demand to build parcel handling and warehouse facilities faster and with shorter lead times.

This trend is likely to continue as we see relatively new end-users influence the entire market with their culture of rapid change and decision-making. This growth, however, is putting more strain on the labor market—which, in turn, is driving more companies to automation.

Most manufacturers rely on a range of manual, semi-automated and automated equipment and systems. The most efficient manufacturers employ software solutions that solve for several needs—including cataloging, calculation, space configuration and more.

SMART SOFTWARE DELIVERS QUICK, EFFICIENT AND ACCURATE WAREHOUSE DESIGN SOLUTIONS

Dealing with a myriad of in-house software tools and long lead times, manufacturers continuously struggle to meet industry demand for fast quotes and realistic visuals of engineered systems prior to a customer purchase.

Improving the sales and ordering process for warehouse solutions can solve for these demands and lead to enhanced safety and compliance measures that benefit both workers and business outcomes.

Here are four companies that employ smart software to achieve specific material handling goals:

| Troax: A Sweden-headquartered metal-based mesh protection panel solutions company with a presence in over 40 countries. Troax is a market leader for metal-based mesh protection panel solutions used in machine guarding, warehouse partitioning and property protection. To stay competitive, Troax’s sales team sought a software solution to deliver customers’ demands and sell their products quickly and efficiently. |

|

Talos: Based in Lewisburg, Tennessee, USA Talos manufactures components for the parcel packaging industry. In 2019, Talos partnered with Configura to develop a solution that would let its customers design systems faster. The company’s goal was to cut engineering time in half. |

|

AJ Products: A prominent player in the Nordic and European markets that has been a leader in the office, warehouse and industry interiors for several years. Offering everything from pallet racks to copy paper through its online catalogue—AJ Products sought to expand. Instead of putting money into building a large team of people to process orders, they opted for a more efficient technology-based approach. |

|

Spacesaver: Based in Fort Atkinson, Wisconsin, USA, Spacesaver is an innovative steel manufacturing company that makes space-planning solutions—including shelving, storage and mobile carriages—for education, military, healthcare, general business and, most recently, industrial markets. Each of their 50 distributors spread out globally varies in size and product offering, but what they all have in common is that 100 percent of their orders go through smart software. |

CET FOR MATERIAL HANDLING

At Configura, we supply innovative software solutions to simplify and speed up layouts, quotes, visualization and ordering of warehouse solutions for leading companies in the material handling industry.

System integrators, manufacturers of pallet racks and conveyors and third-party logistics (3PL), use our software to streamline their sales processes and stay ahead of the competition.

From pre-sales to installation, laying out conveyor or pallet racking solutions is complex. For manufacturers, high customer expectations and the demand for quick turnaround has forced companies to re-evaluate how they do business and the tools they use and maintain. For system integration, the era of digital transformation and high customer expectations has forced System Integrators to re-evaluate how they do business.

As material handling technology continues to evolve, a tool like CET will play an important role in simplifying the process for configuring and visualizing warehouse systems while accurately solving for the safety and compliance needs that help protect workers.

SUBSCRIBE to stay up-to-date on software news and trends

Subscribe to the Configura Blog to get notified whenever we post something new: