User of the Month – Ricardo Rodriguez from Dematic

Ricardo Rodriguez is a Mechanical Engineer at Dematic in Plano, Texas, USA.

Ricardo Rodriguez developed a love for all things mechanical as a teenager while being employed at his dad’s mechanical workshop. In disassembling and reassembly his first brake system, he realized he had a knack for understanding how mechanical systems function. In high school, he zeroed in on his interest and later attended the University of Texas at El Paso to study mechanical engineering.

Over the years, Ricardo has used a variety of AutoCAD software and related tools as a mechanical designer. With a decade of experience in the engineering field, Ricardo joined Dematic in 2021 to help support the company's Mechanical Engineering Team. Learning CET Material Handling was one of his first tasks.

We recently caught up with Ricardo to unpack his design experience and learn about his use of CET Material Handling. In addition to our one-on-one interview, Ricardo completed a CET Challenge—giving him 10 minutes or less to create a small warehouse conveyor loop from a blank digital canvas to a 3D rendering.

To make the experience a little harder, he was asked to answer additional questions while drawing in CET Material Handling. Check it out:

Configura: How did you get into this line of work?

Ricardo: I’ve always had a mind for mechanics. As a kid, I worked with my dad in a mechanic workshop and it all just stemmed from there. After high school I attended the University of Texas at El Paso and sought career opportunities withing the design field. I spent several years working as a Mechanical Designer for TSK Innovations—they even supported me in my pursuit to earn a master's in mechanical engineering.

After the TSK facilities in El Paso were relocated to Mexico, I transitioned to my role as a Mechanical Engineer at Dematic. One of the first things I was tasked with at Dematic was to learn and train in CET Material Handling because it’s the primary tool for our team of mechanical engineers.

Configura: What do you enjoy most about your role as a Mechanical Engineer at Dematic?

Ricardo: I get to use science and problem-solving skills every day. The ability to find answers when I am looking for a part or creating a new layout or design is a good challenge.

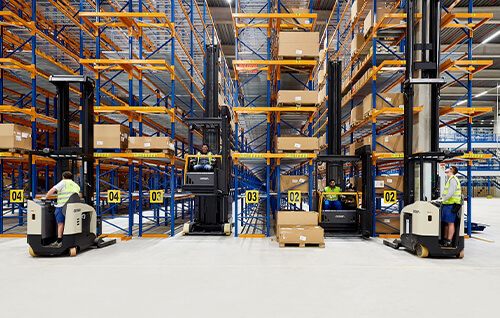

Dematic has a CET Extension (e.g., an Extension is a manufacturer-specific bundle containing resources like price lists, 3D models, images, text and programmed logic) and we are always enhancing it for our design team and our end customers.

Whenever we find something that can be improved or added to our Extension, our team comes together to talk through what, how, why and when. I enjoy participating in those meetings and helping to set the standard for what our Extension can be. I also get to check on updates that are implemented.

This work is about creating solutions. I’ve had the opportunity to try many different software platforms and I have to say, CET is amazing. When I started at Dematic, CET was a new tool for me. But I was able to pick it up quickly.

Configura: In your time at Dematic, what project are you most proud of and how did CET Material Handling help support your design process?

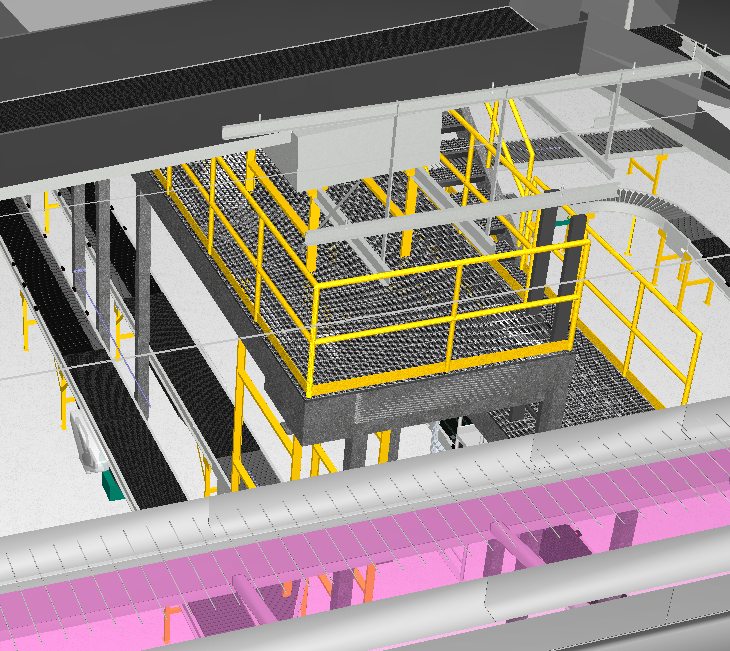

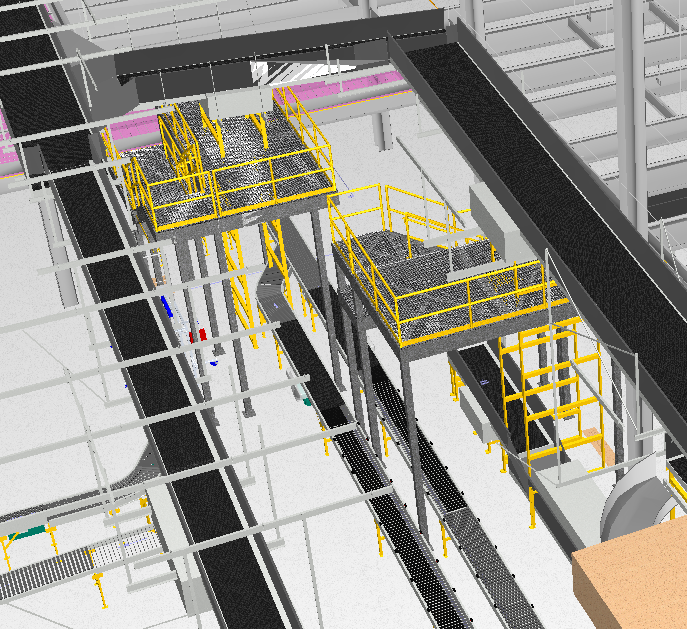

Ricardo: The first project I ever worked on at Dematic was the most challenging to date—but it’s also the project I’ve enjoyed the most. Right from the starting gate, I was tasked with designing three separate platforms for three different warehouse facilities owned by one company. The platforms hadn’t been considered in the original design, but the customer requested the additions specifically.

With initial training in CET, I worked my way through the project, overseeing the designing of the platforms. It was my first time working on a project like that and CET made my job easier, that’s for sure.

I was able to design without any major changes from the client. It was a complicated drawing in that the platform was meant to hover over a spaghetti of conveyors, with very narrow access to place structural support beams.

It was tricky figuring out how to make the platforms work in each warehouse. Any mistake in the drawing would have required the redesign of conveyors and other already complete assets. And that sort of redesign is always costly.

I had to draw a platform for each specific building—I couldn’t just create one platform and place it in each building. Using CET, I could take pieces and parts from one platform and then stretch and adjust it to meet the needs of each building.

CET helped me immensely. The use of 3D visuals, especially, helped ensure I was avoiding overlapping any existing equipment around, below and above the platforms.

Configura: What are your go-to CET tools?

Ricardo: Most of the time I work using the MSC Case tool, which is where I find all the conveyors we use in our projects. The Unit BOM tool is great to check the bill of materials of the units we are using. I also use the 2D and 3D paper space to finalize the drawings we share with customers.

I believe CET has changed how I do work and how a lot of people in this industry are engineering spaces. AutoCAD is still out there, and some people use it really well. But, with CET you are building 2D and 3D at the same time and you don’t have to go back and forth to check. You can manipulate solids or 3D representations to be what you want and need. Plus, the bill of materials (BOM) is created at the same time.

I like that you can create rules while you are building, so if you need specific parts you can accommodate for that. CET is a very helpful tool because at the same time as you are creating something, the build materials are already there.

In my line of work, I often need to adapt the settings of conveyors to match customer requirements. In CET I can do that and even adjust specifications.

For example, the speed of a conveyor should match the customer requirements. We refer to that as the feet per minute and it is related to the horsepower you need to supply the motor that runs the conveyor. In CET, you can specify in the drawing to account for those needs as well. So, it’s a visual tool but it is also a way to place, double check and verify necessary mechanical specifications in a drawing.

I don’t do a lot of the 3D rendering work, that falls to another team at Dematic. But the fact that I was able to do the CET Challenge and demonstrate how I use it every day just goes to show how simple the platform is to learn and use!

Configura: What trends are you seeing in the material handling industry right now?

Ricardo: The ability to work remotely without the loss of quality is a big one. Customers want answers that are accurate and quick. Using a platform like CET, I can create solutions while we are still in the field or onsite—there's no waiting for me to get back to the office. I am seeing this more and more.

Configura: What are your goals for the next 5 years and how can Configura help support you?

Ricardo: I intend to become an Engineer Manager at Dematic in the coming years. Configura is already helping to make that happen by giving me access to a platform that helps me deliver quality work. I am using CET to learn more about the material handling industry and test different scenarios and resources.

When I am not working, I really enjoy spending time with my family. I want to make sure I am present for them and for the things I like to do. I’ve been known to step onto the basketball court regularly—I’m in a 40+ basketball league right now and it’s a really good time. Plus, I just started playing golf, which is quite a challenge!

To read additional CET User of the Month profiles, see the Community tab on Configura's blog page.

Do you want to be our next User of the Month or are you interested in nominating an outstanding colleague for the honor? If so, apply for consideration today!