Why Automation and Robotics are Winning the Material Handling Industry

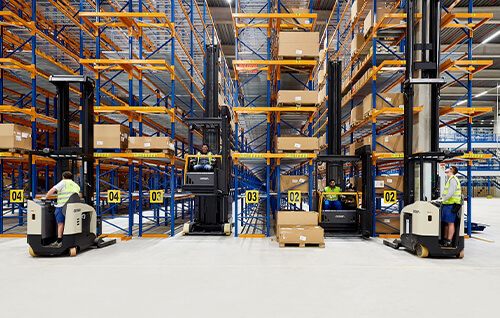

Warehouses are filled with repeatable, process-oriented and error-prone operations. When smart technologies like robots work in tandem with humans, processes including order picking, receiving, handling, safety and training become much more efficient and predictable.

A case for robotics and automation

A large amount of labor in a warehouse is segmented for “walking search” or the process of workers walking around a warehouse searching for inventory. Order picking is often a laborious and time-consuming process.

The use of robotics is both affordable and practical, especially as innovation and ways to do it become mainstream.

For the material handling industry, robots can help create a safe and orderly warehouse by ensuring goods and materials are properly stored, easy to find—workers spend far less time searching—and transported correctly.

In addition, automating processes can accelerate the delivery of goods to customers, prevent workplace accidents and improve facility efficiency.

Automation can take many forms. Something as simple as pallet racking is essential to any efficient warehouse operation. With the use of a robot palletizer, the process of placing goods or products onto pallets becomes more safe, accurate, cost-effective and controllable.

Two major reasons to invest in warehouse automation

|

%202.jpg?width=3840&height=2100&name=EPR%20Automation%207%20(UI%20Screenshot)%202.jpg)

Subscribe to the Configura Blog to get notified whenever we post something new: